Bishops Printers, a UK-based leading provider of printing solutions, is counting the benefits of Fujifilm’s Superia ZX plates. Bishops Printers, operating from an 80,000 sq. ft. facility and employing 200 staff, has a turnover of approximately £25 million. Specialising in general commercial printing, the company produces a range of products including saddle-stitched brochures and leaflets for a diverse customer base, manufacturing over 2,000 jobs a month.

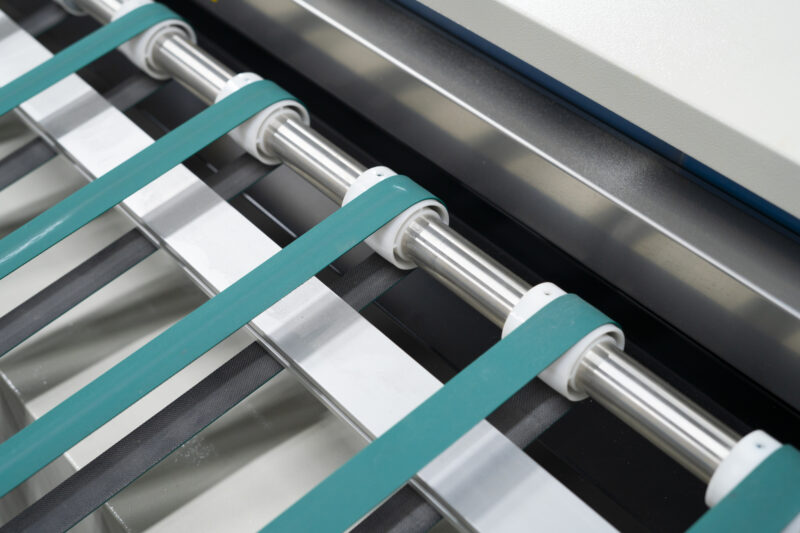

Bishops Printers’ relationship with Fujifilm spans nearly two decades, initially investing in Fujifilm’s Superia LH-PLE CTP plates, and more recently, switching to Superia ZX processless plates. The Superia ZX plates have proven to be a reliable investment, resulting in enhanced sustainability, efficiency and print quality, while leveraging the robustness of on-press development (OPD) technology to streamline operations.

With a rich history rooted in high-volume printing, Bishops Printers understands the importance of producing quality printed products promptly. Gareth Roberts, Managing Director, Bishops Printers comments: “Fujifilm’s Superia ZX plates offer excellent on press development and start-up performance, ensuring stable print quality across varying paper types, whether roll or sheet-fed.

“The operators find the visibility of the image on the plate enables them to handle it quickly and smoothly, and the lack of scratching or marking enhances productivity. The company now uses fewer than 100 sheets per make-ready across more than 5,000 make-readies per month, achieving make-ready times that were previously unattainable.

“Moreover, we benefit from the exceptional handling capabilities of Superia ZX plates, particularly in scratch resistance. Equipped with a full press automation system, we seamlessly transitioned from LH-PLE to ZX, experiencing minimal downtime and no issues with scratches. This swift switching process further underscores the reliability, consistency and efficiency of Fujifilm’s Superia ZX plates.”

In addition to process efficiency and print quality, Bishops Printers emphasises the environmental benefits of using processless plates like Superia ZX. “By eliminating the need for chemicals and reducing waste paper, we are contributing to a greener printing process while also experiencing labour savings and faster output times. Overall, we are thrilled to integrate Fujifilm’s Superia ZX plates into our printing processes, aligning with our commitment to delivering quality prints efficiently and sustainably.” adds Gareth.

“Fujifilm has been an excellent supplier to work with over the decades. The reliability of the product has of course been incredibly important, but it’s the service that we really value in a working relationship that has enabled us to work with Fujifilm as a trusted partner for so long.” concludes Gareth.

“We are proud to support Bishops Printers in their journey towards sustainable and efficient printing solutions.” said Sean Lane, Product Management and Support Manager for Offset Products, Fujifilm Europe. “Superia ZX plates not only offer exceptional performance but also align with our shared commitment to environmental stewardship and operational excellence. We look forward to continuing to develop our relationship with them as we watch their business grow.”

www.fujifilm.com