Following a successful beta test, German online print shop SAXOPRINT GmbH is transferring an HP Indigo 100K into regular operation. This is the first time that the company has added an HP Indigo digital press to its machine park. A subsidiary of CEWE Stiftung & Co. KGaA, SAXOPRINT has over 20 years of experience in offset and digital printing. In addition to office equipment such as business cards, stationery, brochures, flyers and folders, the approximately 500 employees strong print service provider is also responsible for advertising technologies such as roll-ups, covers and promotional items across Europe.

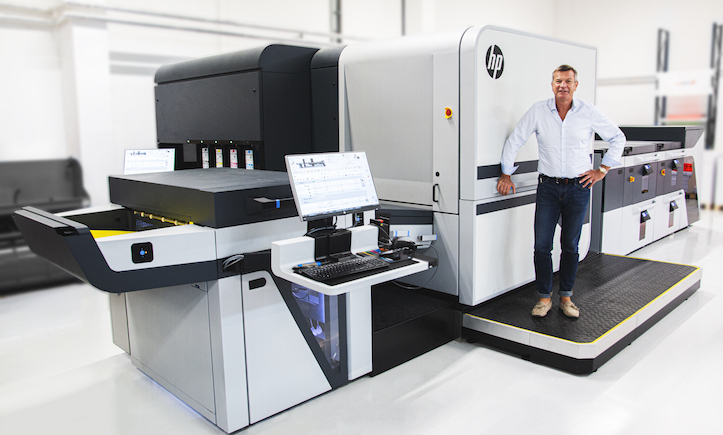

“We have been able to properly test the HP Indigo 100K since mid-2019. Up to this point, we did not have any experience with an HP Indigo press. However, our parent company has been relying on the quality of the HP Indigo presses for many years and we were quickly convinced by the technology in the test run, too. The installation of the machine, as well as the onboarding and the training went very smoothly and without any problems,” said Klaus Sauer, Managing Director of SAXOPRINT GmbH.

A decisive factor in the installation of the HP Indigo 100K was the smooth integration of the press into SAXOPRINT’s existing hybrid workflow and its machine park. “In our hybrid production environment, offset and digital presses coexist productively side by side, enabling us to achieve high added value and maximum efficiency,” emphasized Sauer. At SAXOPRINT, every uploaded job goes through an automated data check and ends up in a queue, depending on the type of job and subsequent finishing. After a waiting period, the jobs are bundled and automatically set to form. The collective forms are then transferred to the appropriate processing points (plate copy or digital printing) and printed. “The HP Indigo has seamlessly integrated into the system and complements the existing presses perfectly,” said Sauer.

In addition, the print quality and high productivity of the HP Indigo 100K with a print volume of up to 6,000 B2 sheets per hour was convincing. Advanced functions such as inline colour calibration, convenient and uninterrupted paper supply and stacking also offer a high degree of automation.

“Today more than ever, the degree of automation is decisive for the cost-effectiveness of the entire production process, which is why we are constantly optimising it. We assume that the proportion of products that are printed digitally will continue to grow in the future and with the HP Indigo 100K, we are well equipped for this,” said Sauer.

The HP Indigo 100K Digital Press is designed for high productivity required by offset players to transition more work to digital and boost sustainability with on-demand printing. The HP Indigo 100K uses advanced paper handling and offset-like gripper-to-gripper design for precision registration, while adding boosted digital capabilities, including a five-input source feeder, colour automation, calibration and fast switchover between jobs and media.

www.hp.com