Climate crisis is one of the most immediate global concerns. Companies worldwide are realising their crucial role in achieving social and environmental goals, particularly in combating climate change. As part of Konica Minolta’s sustainability strategy the company pursuits the Sustainable Development Goals (SDGs) [1] and participate in the 50 Climate Leaders.

Sidebar

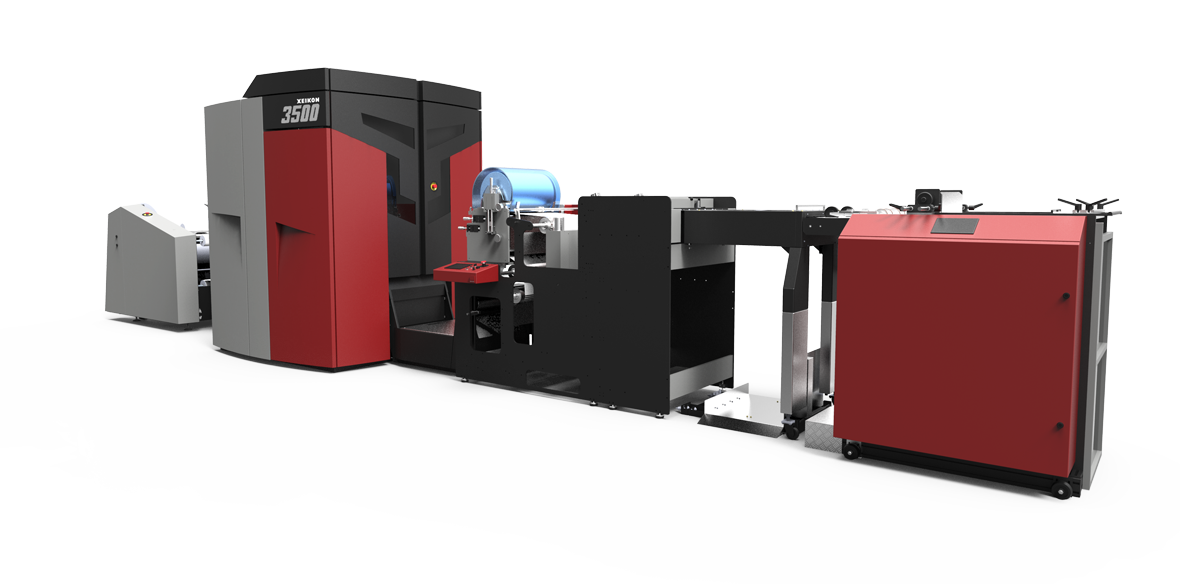

Future-proofing printed folding cartons

Getting ahead with a folding carton suite

There are two ways in which a digital carton printing machine can complement your business. Either you have already been confronted with new orders demanding more flexibility by smaller lot size and a faster response: then a digital suite is your answer right there. But even when your business consists for the most part of offset jobs today, a digital suite could open new doors: you get to show your customers new possibilities, improve your relationship with them and attract new ones too.

Commercial printer wants to grow further with Push to Stop concept through autonomous printing

Micropress Printers Ltd. invests £4 million in new Heidelberg press and paper warehouse

New Speedmaster XL 106-8-P can process up to 30 jobs automatically

High productivity and color stability important criteria for almost 24/7 operation

Simple and cost-effective sheet outfed

The PST-52 feeds single sheets either via the outfeed of the CS8 cross cutter, the LS8 stacking module or the TB8 transfer.

The new X-Rite eXact Auto-Scan

Digital Information’s InkZone Move and X-Rite’s eXact Auto-Scan are bringing affordable color bar measuring and online offset press control to web and sheetfed printers worldwide.

Screen Truepress Jet520HD Seamlessly Delivers ‘Book of One’ Production At PrintOnDemand-Worldwide

As part of its continual pursuit for highly automated, seamless book production, PrintOnDemand-Worldwide (PODWW) has gone live with a SCREEN Truepress Jet520HD press — the world’s first inkjet printer using specially developed SC inks to print on standard litho coated paper without priming or coating treatment.

New high-performance system for creasing and perforating

A typical problem when processing digital prints or other delicate material is the cracking of the toner layer along the fold line, which has a negative effect on the quality. Creasing along the fold line can considerably reduce or even avoid this phenomenon. For these applications MB Bäuerle has developed the creasing system WF-D2H high pile. With the creasing technology used in this system, the material is gently compressed, because the excessive stretching of the paper fibres is avoided. This principle prevents cracking of the printing ink or tearing of the paper, thus ensuring optimal after-print processing.

Xerox Offers Behind the Scenes Look at Epic Book Collaboration on SetThePageFree.com

See intimate glimpses into the work style of award-winning, international authors like Lee Child, Roxane Gay, Billy Collins and others

Tech-ni-Fold release video explaining their simple solution that takes creasing to a new level

Applying a crease to eliminate digital fibre cracking is taking on a whole new meaning according to Graham Harris, Managing Director of Tech-ni-Fold and inventor of the Tri-Creaser. Due to the increased numbers of recycled paper coming through the supply chain, flaking and slight cracking can randomly occur on the inside of the creased product, often identified by a white broken line visible each side of the crease bead.

Xerox Solid Ink

By Cheryl Otstott, Xerox

Xerox solid ink, let’s take a look at these big crayons. That is what they are big blocks of resin-based non-toxic color that are melted in the printer and affixed to the paper through heat and pressure. They create a great image. Printers that use solid ink require no special paper and the prints do not curl or wrinkle like other color laser or inkjet printers.